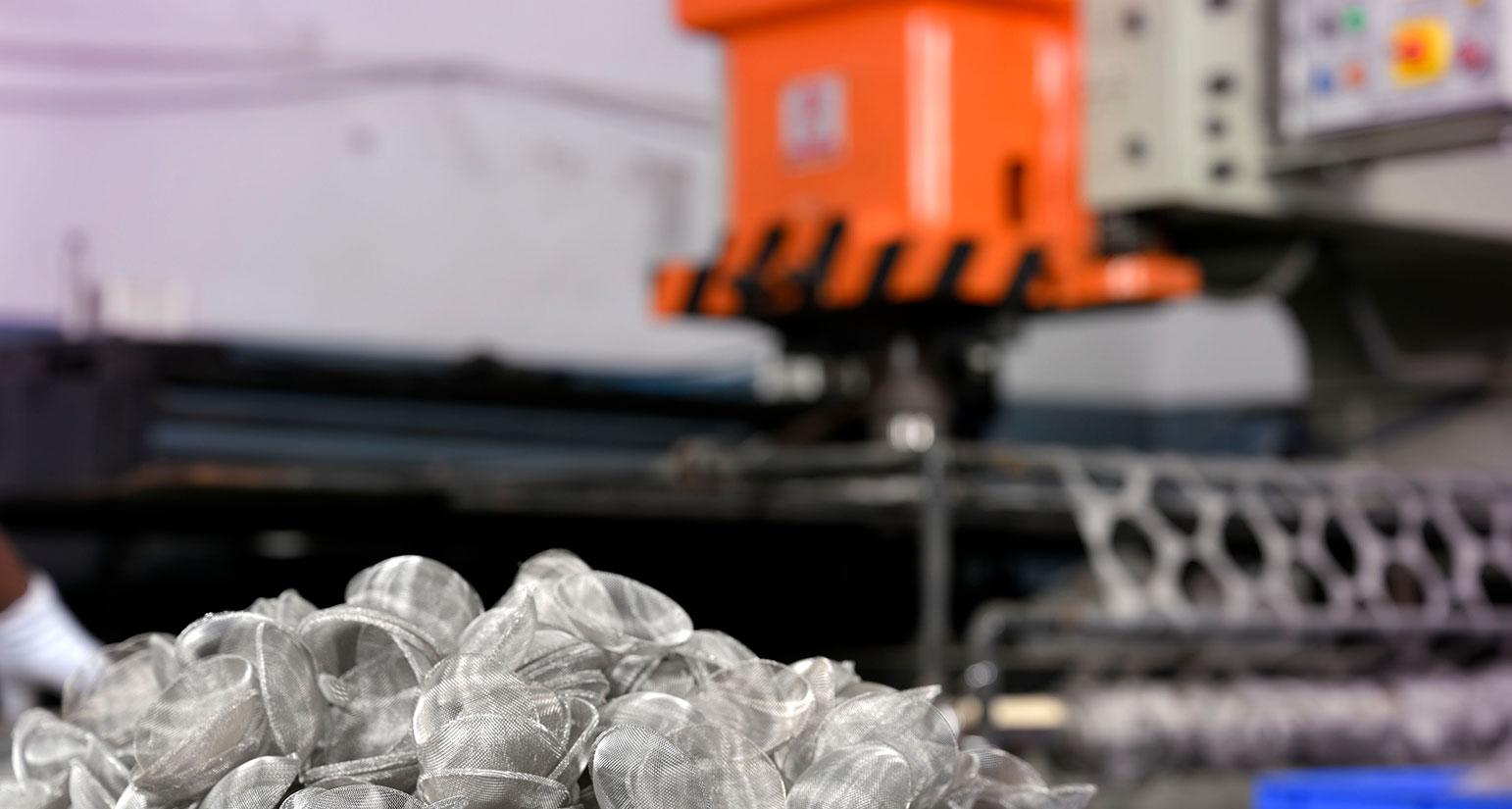

Spanning 27,000 sq.ft our meticulously designed production facility pays attention to even the smallest design and structural details.

The factory layout, systems, and supporting infrastructure are closely guarded secrets, honed through years of experience, setting us apart from the competition. Over the past 25 years, we've built an infrastructure capable of manufacturing high-quality products that rival any international brand, emphasizing quality, mass production, and timely delivery.